Upgrading train diesel engines is a very positive move when installing an Opti Combustion set of pistons that enhance efficiency within the same prime movers. Depending on the condition of the existing pistons we can reuse them to save on costs.

While understandable to focus on the cost of diesel fuel and AdBlue for your locomotive or DMU, there is another costly fluid in the equation which is lubricating oil.

With an Opti upgrade the engine’s lubricating oil does not suffer from black carbon build up from blowby in the cylinders and lasts twice as many working hours as would typically be recommended, thus halving this cost over the life of the tractor.

Cleaner Opti Combustion piston upgrades benefits everything, namely:

• Fuel combustion efficiency meaning around 20% greater fuel economy for better range from the same tankful and considerable cost savings.

• Around 80 degrees centigrade cooler exhaust temperature along with smoother quieter running.

• Substantially lower NOx and unburnt fuel emissions from the heart of the engine rather than via sophisticated and expensive after-treatment which is prone to developing faults.

• Develop more power and torque at lower RPM by drawing in more air quicker and triggering the turbo lower down for better driving characteristics.

So, what is the Opti Combustion process then?

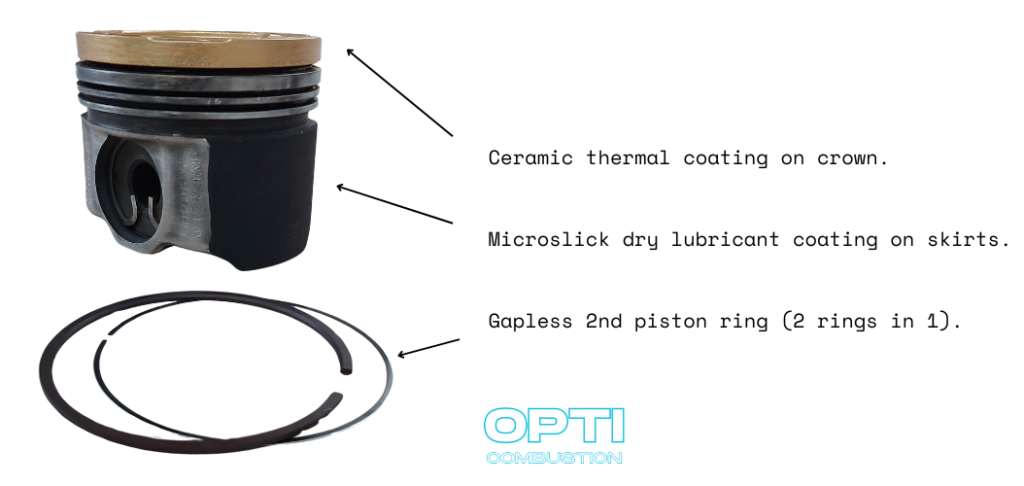

It enhances the pistons by adding a thermal ceramic coating to the crown area, dry lubricant coating to the skirts, and gapless high-quality piston rings as are used in racing car engines.

Blowby is the enemy of all engines; it involves partly burnt carbon from fuel making its way down into the crankcase/sump through the ring gap around normal piston rings. This is why when you change a diesel engine’s lubricating oil it is black but there can also be problems the other way with lube oil making its way into the combustion area.

Fitting gapless rings revolutionises the engine’s performance leading to less stressed operation, longer service life at lower costs and as a bonus emits less air pollution or damaging hydrocarbons!

It is transformational and perhaps best of all it is a mechanical technology. What do we mean by this? Well, more electronics in engine management is all very well and useful in modern locomotives or DMU’s but guess what? It is also a) more to go wrong and b) very costly when it does go wrong.

With our upgrades, you are looking at an invasive engine rebuild which is not cheap, but it fundamentally alters and upgrades the prime mover’s central process in what happens in burning diesel fuel and making power for your needs.

It boosts reliability and reduces operating temperature (a serious problem on some MTU engines in Hitachi Class 801 DMUs in the summer months), doubles the oil’s life, and cuts stress on the engine.

If it works for you to remove the pistons yourself and then send them over for upgrading then that is fine, we can do this with no problem for you to rebuild the engine yourself.

Please be free to reach out to us on 01324 309100 or email: oil@lubiq.uk